A Mobile Parlor

Unit can be moved for better access and added capacity

BY Wilfried Wesselink

Editor’s note: While this system has yet to reach North America, it offers a unique approach to special needs milking.

Do you have a barn that’s too distant from your milking parlor? Do you need extra parlor capacity? Or do you have a distant special needs facility that could use a better milking system?

Europe Dairy Systems, headquartered in the Netherlands, has developed a single-side, six-stall parlor called the Mobistar 2G6 that can be placed just about anywhere cows need to be milked.

Bonus Content | |

| Video of mobile parlor |

The system was developed in Europe for smaller herds and graziers, but it is being used by ex-robot dairies and commercial dairies with special milking needs. And, if a farm can’t get financing for a conventional parlor, the Mobistar is available for lease.

Because it is mobile, financing is a bit easier, as well. The 2G6 is not a fixed asset with poured-in-concrete footings and basements. If a farmer defaults on a loan, Europe Dairy Systems guarantees the lender it will buy the parlor back at 90% of the original value.

The most innovative aspect of the 2G series is that the floor where the cows stand can be hydraulically moved up and down, says Rutger Schut, director and owner of Europe Dairy Systems. As a result, there is no need for a milking pit, and the cows do not have to walk up or down any ramps.

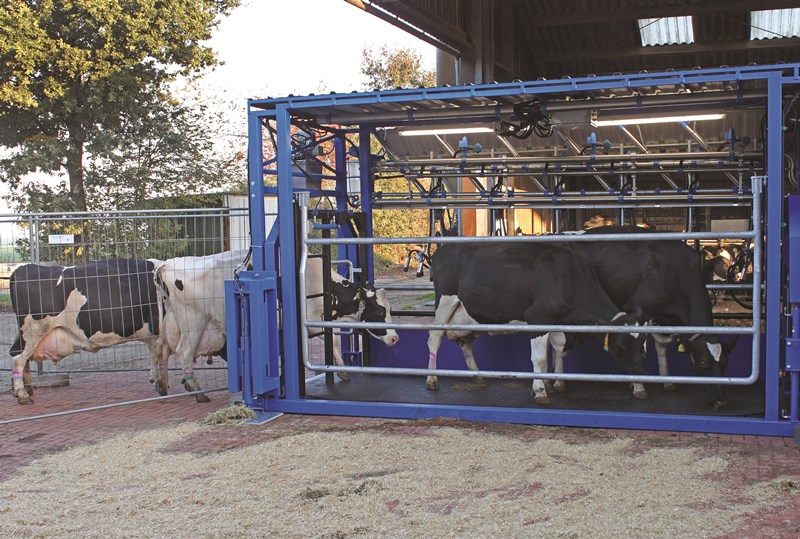

The platform is 6½' wide and 25' long and can accommodate six cows. The cows enter the parlor at the front and then turn 90°, where they line up side-by-side to be milked.

To prevent cows from moving too much during milking and pushing one another out of the way, there is an option to mount dividers on the bar of the front holding fence. This option might be useful for new stock and young cows as they get acclimated to the system.

|

Cows enter the parlor at the front, walk up and then turn 90°, where they line up side-by-side to be milked. |

|

When the cows are in place, the hydraulic floor raises the cows 31" above the ground for milking. |

|

After milking, the platform is lowered and the barrier in front of the cows is raised so cows can simultaneously walk off the platform. |

The parlor operator only has to press a button and four hydraulic cylinders raise the platform, with the cows on it, about 3' above the ground in about 10 seconds. Another push of the button after milking is finished allows the platform to lower back down to the ground.

The barrier in front of the cows is then automatically raised up, and the cows can simultaneously leave the platform by walking forward, straight off the platform. The system can be configured to hold up to 12 cows per group and can average five to six groups of cows per hour.

"It’s actually a very simple system," Schut says. "I figured it out on a rainy Sunday afternoon and put it on paper for Eastern European dairy farms. Because it can provide a solution elsewhere, we have also patented it for worldwide use."

Milk cooling is done by a combination of propane gas, water and glycol, and ice bank cooling. (The cooling system was initially developed by the Dutch company ICEK for fast and sustainable cooling of Heineken beer barrels used at festivals.)

During the milking process, the milk goes through a plate cooler, which reduces the milk temperature to 68°F. Then, cooling is taken over by an ice bank system, where it is further cooled to about 38°F. By combining these different cooling principles, the process uses at least 45% less energy than the conventional propane refrigeration systems.

Dairy producers who want to use the mobile milking parlor in the field during the summer can also purchase a diesel generator, hot water tank and trailer setup. It also includes a milk tank ranging from 400 gal. to 1,200 gal. A tunnel tent that goes over the parlor during inclement weather is also available.