Architect Of Innovation

Young farmer diversifies by producing energy from food scraps

Dairy producer Chris Noble opens a door in the refrigerated section of his local Wegmans grocery store and pulls out a carton of Siggi’s Icelandic-style yogurt. He points to the number 36 stamped into the bottom, a reference to the fact the product inside came from New York.

|

In fact, Chris has an edge on most consumers who put this yogurt in their shopping carts: The creamery he helps manage is one of a handful of milk suppliers for the Siggi’s brand, a high-protein, low-sugar alternative

to Greek yogurt.

“Seldom do dairy processors need all the components in farm milk to make their product. Oftentimes they might need more or less butterfat than what comes out of a cow, or maybe they need just the protein in the milk,” explains Chris, 34. “If we can produce standardized milk and cream products efficiently and deliver it when and where they want it, that’s our goal.”

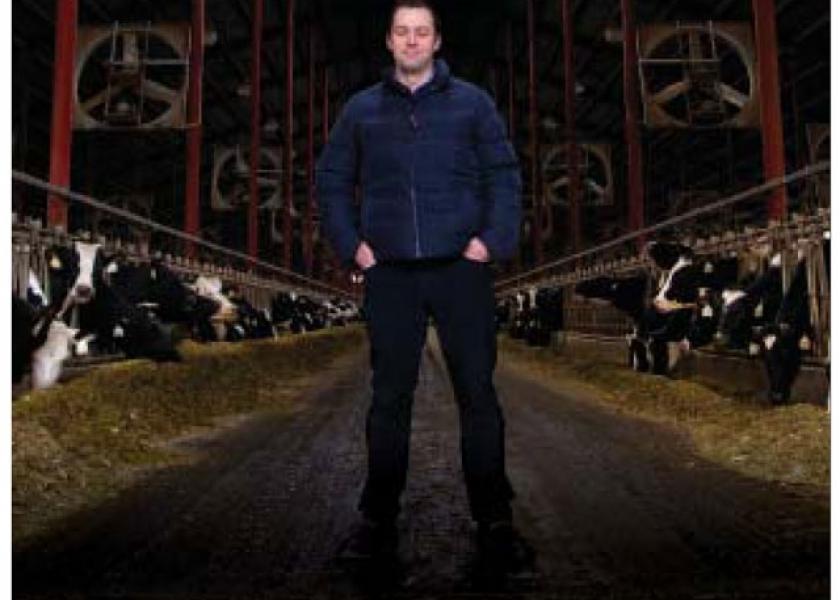

Chris is just as comfortable in a high-end grocery chain as he is managing manure at his family’s 1,800-head Holstein dairy operation, known as Noblehurst Farms. He is a master at connecting the dots of production agriculture, biological processes and consumer trends.

In doing so, he has built a reputation for launching and overseeing innovative side businesses. In addition to the dairy with milk serving East Coast processors, the operation has 2,800 crop acres for feed production; and investments in Craigs Station Creamery, a cold milk-separation facility that uses milk from the dairy; Noblehurst Green Energy, including an on-farm digester that produces electricity; and Natural Upcycling, a food-scrap collection business.

“He’s observed well,” notes Sarah Noble-Moag, Chris’ aunt and a sixth-generation owner of the dairy. “He listens well. He sets a great example for other young folks coming into an established business.”

It’s for those reasons Chris is the 2016 winner of the Tomorrow’s Top Producer Horizon Award, an annual distinction that recognizes a farmer 35 and under who demonstrates entrepreneurial originality, financial and business progress, and leadership in industry and community.

Energetic Leadership. Chris represents the seventh generation of leadership at Noblehurst Farms, where he holds the title of vice president.

He spends roughly 40% of his time on the digester and Natural Upcycling; another 20% on the creamery; 20% performing various functions at the dairy; and a final 20% on industry functions, financial reporting and risk-management activities.

He enjoys managing finances and margins, skills he honed as a risk-management expert at Brock Associates agricultural marketing service and as an analyst for Rabobank. Dairy markets became his specialty when he returned to the farm full time in 2009.

“I really spent some time learning about the mechanics of the market,” Chris explains. He notes “fairly strong” milk prices for several years after 2009 enabled his family to invest capital in other places outside the traditional dairy, paving the way for his own interests to flourish.

Chris’ father, John, is president of Noblehurst Farms, which began in 1960, and Chris is part of an executive committee that manages its various enterprises. He notes the operation has been enterprising since its foundation.

“I take great pride in saying I’ve done pretty much every job on the farm,” Chris says. “It builds trust in your judgment. People know that I won’t ask them to do anything that I wouldn’t do myself.”

In many ways, Chris is continuing a long family tradition, notes Dean Norton, senior agricultural consultant with the farm’s CPA firm, Freed Maxick & Battaglia.

“Noblehurst Farms has been a leader in the farming community using new technologies, dairy innovations and cropping practices for many years,” Norton says. “With Chris’ vision and insight, they have continued that leadership as they move into the green and sustainable energy arena.”

Manure Power. A fire forged the path to Noblehurst Green Energy. In 2011, the family’s 130-kW generator that had powered the farm for a decade caught fire, torching the surrounding building in five minutes. In the aftermath, Chris received the task of regrouping and identifying a new way forward. After months of research and planning, Chris recommended the farm pursue a relationship with EnviTec Biogas of Germany.

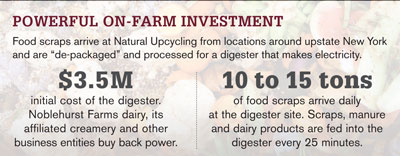

The farm brought the $3.5 million digester online in April 2015, and the operation expects to recoup its costs in seven or eight years. The 450-kW machine produces roughly 10,000 kwh of power daily that feeds into the dairy, the creamery and surrounding homes in the rural community. Although Chris is a proponent of solar—the creamery has an array on its roof—he says digesters have an edge.

“Biogas has the advantage of reliability, producing power 24/7 instead of when it’s windy or sunny,” he says. He says such power is meaningful to provide baseload power to supplant fossil-fueled plants.

The digester saves the dairy $100,000 annually in energy costs.

Liquids from the digestion process are applied as fertilizer to the farm’s crops, which produce feed for the dairy cows. This process also reduces the smell of manure. “It helps with our community relations,” Chris says.

The digester can’t function optimally on manure alone, which created an opportunity to work closely with retailers and food manufacturers. Each day, the digester is fed a liquid mix that consists of 65% manure, 25% dairy products and 10% food scraps.

Dairy farmer Skip Hardie has known Chris from birth and serves with him as head of the state’s Dairy Promotion Advisory Board.

He has taken family enterprises and “shaped them into long-term, economically viable, socially responsible and environmentally friendly operations,” Hardie says.

Scrappy Setup. A cold phone call led Chris into what is now Natural Upcycling, a company whose fleet of four vehicles collects pre-consumer food scraps from 33 Wegmans locations and numerous other for-profit and nonprofit businesses.

His now-business-partner, Harry Cohen, had called the dairy to ask about partnering for a trial run with six Wegmans stores, and the venture led to a booming market. The two forecast more opportunities to expand as New York looks to impose foodwaste bans to reduce methane emissions from landfills.

On a recent winter day at the Noblehurst Green Energy facility, located near the dairy, a worker unpackaged mounds of outdated blackberries for processing. Inside, workers opened boxes of flavored coffee syrup. Bottles are thrown into a machine that squeezes the liquid out for use by the digester.

The Noblehurst Green Energy digester receives roughly 10 tons to 15 tons of food scraps daily, though other locations used by the company handle additional volumes.

As part of his responsibilities, Chris must provide documentation to retailers that the food leftovers have been destroyed—not repackaged and sold under a different name. The operation leaves plastic food-scrap bins at Wegmans and other retailers and collects them multiple times every week for processing. The businesses pay a fee to Natural Upcycling to pick up and process those materials. He admits it’s risky to be “a jack of all trades and master of none,” but Noblehurst Farms sees value in these businesses in light of regulatory trends.

His business partner, Cohen, notes Chris isn’t one to brag about his accomplishments growing the food-scrap business, which will soon add up to 10 more Wegmans locations.

“I didn’t know I was working with one of the greats,” Cohen says. “He’s so humble.”

Cream Of The Crop. Although food-scrap collection involves more interaction with retailers and organizations than farmers, Chris’ work at Craigs Station Creamery is centered around neighboring producers.

At peak daily capacity, the creamery processes 1 million pounds of milk and handles up to 15 trucks, each of which holds up to 8,000 gal. of milk. Eight local farms located within a 30-mile radius sell milk through the facility. Noblehurst Farms is positioned just 1,000 ft. away.

| |

The main dairy facility at Noblehurst Farms has 1,800 Holstein cows, which are milked three times daily. The cows eat 100 lb. of feed and drink up to 50 |

Chris notes the farms’ close proximity and careful monitoring of milk supply tells a story of farm freshness and traceability to consumers who buy products made by milk processors.

The creamery produces skim milk, standardized milk and cream. Dairy Farmers of America runs the $12 million plant and cuts checks. “It was the first example in the country of a dairy cooperative investing in a facility alongside its member-owners,” says Chris, who is liaison to the seven other farms participating in the site.

Generational Growth. In many ways, Chris is much like his great-grandfather, an entrepreneurial man who started Noble Farm Service, a former John Deere dealership that now specializes in lawn-care equipment, and sold blue Harvestore silos that dotted the landscape in the 1960s and 1970s. “He knew the direction he was going,” Chris says. “He was a very convicted and faithful man, and a leader in the industry.”

Chris’ grandfather continued the tradition of passing on management expertise, even though a farm accident ended his life abruptly just two years after John became president of the dairy. “It was a strong lesson of the importance of farm succession planning,” Chris says. “Had he and others in the business at that time not had the foresight to cultivate young leaders, I would not have been afforded the same opportunities.”

Chris plans to continue shoring up leadership and innovating new revenue streams. It is, after all, part of the legacy that has kept his family in business for generations.

|

About Chris Noble

| |

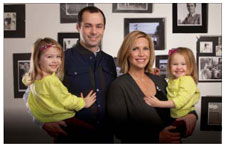

Chris and his wife, Jennifer, have three daughters: Emilie (left), 4; Adelaide, 2; and Isla (not pictured), born Feb. 1. |

Operation: Noblehurst Farms is the umbrella company for multiple profit centers and for which Chris Noble, 34, holds the title of vice president. The corporation includes an 1,800-cow dairy with 2,800 crop acres; and investments in Craigs Station Creamery, a milk processing facility that includes eight farms; Noblehurst Green Energy, a company that produces electricity; and Natural Upcycling, a food-scrap collection business. Other entities are Linwood Commodities, which sells feed commodities as well as fresh alfalfa hay to East Coast dairies; Linwood Turf Equipment; and Synergy, a 1,900-cow dairy in which Noblehurst Farms is a partner.

Team: Collectively, the individual businesses employ dozens of workers from the local community, including about 40 at Noblehurst Farms.

Technology: The operation includes a $3.5 million anaerobic digester for processing manure, milk products and food scraps into a liquid applied to crop fields; a state-of-the-art $12 million creamery, which serves as the front end of operations for milk processors; and four trucks collecting food scraps from more than 30 Wegmans grocery stores and other businesses.

Leadership and Community: Chris is a member of the New York Dairy Promotion Advisory Board, the state’s dairy checkoff, which decides how to use 15¢ of every hundredweight of milk sold. He also helped form New York Cow Power, a group that is lobbying legislators to incentivize construction of digesters on farms for electricity production.

Dairy Consumer Trends in 2016

Among the trends New York producer Chris Noble sees shaping the dairy industry are aseptically packaged products—such as organic milk sold at Starbucks and other retailers—that are sterilized and designed to maintain freshness for months. Specialty packaging for on-the-go consumption also is gaining popularity.

Specialty European-style cheeses including Gouda and Havarti also are growing in prominence, Chris says. As the nation’s Hispanic population grows, cheeses native to Latin America also are becoming more popular. Yogurts with international origins are popular, though they can be risky; an Australian variety for which the creamery sold milk is no longer made locally because U.S. consumers didn’t buy it.

He points out 15% of U.S. milk is exported on a milk solids basis as cheese, whey protein, milk powder and a host of other products. He thinks New York milk has potential in overseas markets as his family’s operation looks at expansion opportunities in the years ahead.

“’I Love New York’ has a global cachet,” Chris says.

....................................

Register now for the 2016 Tomorrow's Top Producer business conference happening June 16-17 in Nashville!