Cue Up Technology: 3 Producers Share Must-Haves and ROI

Optimizing productivity and improving efficiency are top goals for any dairy. They’re discussed in farm meetings, illustrated through management practices and closely monitored in financial budgets. The big-ticket question is, “What can help a dairy producer launch their operation to the next level?”

Cue up technology. During a recent Farm Journal MILK Innovative Dairy Producer webinar, three dairy producers openly talked about technology must-haves and how ROI comes into play when making technology investments.

Fifth-generation Wisconsin dairy farmer Mikayla McGee of Jon-De Farm says her family has plans to add a carrousel parlor, which would allow for them to eliminate milking on two sites and gain efficiencies that cannot always be documented on paper.

“We are planning on building a rotary parlor to gain efficiencies mainly in labor,” she says. “With the addition of a rotary, we will be able to cut our labor force in half and save approximately $800,000 a year. I think we will find several other benefits to having all our milk cows together on one site. We hope to reduce stress during the milking process and increase overall cow comfort with the addition of tunnel ventilation.”

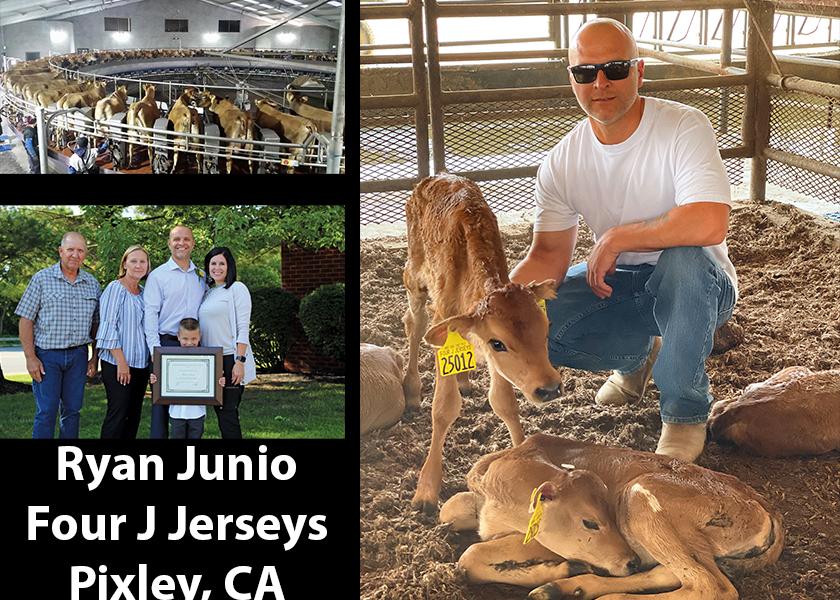

Head west to California and Ryan Junio of Four J Jerseys in Pixley is in a similar situation. His family dairy is building a 2,000-cow freestall barn that will allow them to bring all their cows home to one central location. The move will allow them to expand their methane digester, capitalizing on the methane coming off that additional 2,000-cow facility, as well as better use labor on one site versus two.

“With the freestall barn and methane digester expansion, my primary focus is to gain efficiencies in labor through consolidation of our milking herds as well as capitalize on a different revenue stream by getting all of our cows tied into our methane digester,” Junio explains. “With all the milk cows in one location and housed entirely in freestalls, I will be able to better manage my herd while reducing my labor by 25% and capturing the methane produced by all of our cows.”

Eastern Tennessee dairy farmer John Harrison of Sweetwater Valley in Philadelphia is keeping his options open for future opportunities, as he isn’t quite convinced now is the time to invest in big technologies.

“I’m waiting to see how our dairy comes out of this downturn before making big decisions,” he says.

Return on Investment

While future improvements are inevitable for growth to occur on dairies, these three dairy farmers say carefully evaluating ROI is not as simple as it might sound. For Junio, he would like to see a new project cash flow itself before adopting it into his dairy.

“It depends on the size and scale of the investment,” he says. “If it can pay its own mortgage, obviously that is a home-run idea.”

However, for Harrison, he budgets for a 20% ROI and hopes to get half of that before adopting new technology into his dairy operation.

McGee says calculating ROI isn’t a simple math formula -- there are other factors to consider before adopting new technology.

“If you are not going to utilize all the information the technology offers, then you might need to consider reevaluating a more basic option,” she says.

The Wisconsin dairy farmer witnesses the differences technology offers daily, as they have daily weights in both parlors, as well as use an AFI lab system that offers a pool of daily information.

“If you aren’t doing anything with the information, it’s useless,” she says. “For us, we have found that all we really want from our milking system are daily milk weights to manage our herd.”

Game Changer

The biggest tech advancement for Junio occurred five years ago when they built a carrousel parlor.

“Before that, we were milking on three facilities, with all flat parlors,” he says. “We saw the writing on the wall with where labor was going and the opportunity to consolidate cows, people and increase efficiencies has been awesome.”

Additionally, Junio says adopting sort gates has allowed them to reduce labor and take the stress off the cows by not having to disturb them more than necessary.

For Harrison, who milks 1,600 Holstein and cross cows on four different facilities, including a 500-cow robotic dairy, his game-changer is a contactless payment app called Square. He and his family also run a café and tourism business.

“Both Square and social media have impacted our business tremendously,” he says. “We pretty much don’t advertise anywhere, just use social media.”

Although the robot facility was a big-ticket purchase for Sweetwater Dairy, Harrison understands the robots offer a lot of information and data, but he also says he isn’t 100% convinced his dairy is fully using the technology the robot facility offers to its fullest potential.

“The verdict is out to determine the full ROI on that barn,” he says.

Opportunities Ahead

In Wisconsin, McGee’s herd size has decreased by 8% over the last couple of years and doing so has allowed them to ship the same amount of milk and increase their profitability.

“Sometimes less is more,” McGee says.

Jon-De Dairy needed a new dry cow barn, but instead of building that barn, the family has decided to decrease their herd size to make room in their current facility for dry cows. McGee says downsizing their herd allowed for downtime in the parlor, which gave the dairy time to spend managing their sick pen, fresh cows and overall management of the herd.

“Before we always felt like we were rushing to just get through the chores that we really never had time to make improvements and get better,” McGee says. “We now have lowered our cell count, increased milk production per cow and have more flexibility with labor. We didn’t ‘downsize,’ we ‘right-sized.’”

Out west, big opportunities are on the horizon for Junio, as he signed a contract to start producing A2A2 milk with Land O’Lakes. Through genomic testing, Junio has been able to verify that 65% of his 4,200 Registered Jersey herd are A2A2 positive and Junio expects premiums to grow, which will drive him to eliminate the non-A2A2 cows. Additionally, a large percentage of his milking herd is set up as recipients for Angus embryos.

“We are calving between 200 to 300 Angus calves each month. That generates another avenue of revenue for our farm,” he says.

Like McGee, Junio has reduced his herd size from 4,500 to 4,200. This allows Junio to hone more on genetics and diversification, striving to realize profitability on his farm’s bottom line.

In eastern Tennessee, Harrison’s goals are to make more cheese, sell more milkshakes and increase tourism.

“Ideally we want to produce 800,000 pounds of cheese a year and we feel like we have everything in place to do this,” he says. “This area of the farm is what currently is profitable, so we are hoping to capitalize on this.”

Challenges Ahead

With opportunities, come challenges and all three dairy farmers are aware of this. One echoing challenge from the producer panel is labor, labor, labor.

“Labor is our top concern,” McGee states. “The last five years have not been very profitable for our dairy, and we are starting to come out of that hole and looking at making larger investments and always look at improving efficiencies, especially because labor is so hard to come by.”

At one time, Harrison says, they used to want to find the best labor but now they are just trying to fill vacant spots.

“We are short on help every single day,” he says.

While Junio says labor is a big glaring issue, currently his state is faced with an even bigger obstacle than labor. An ongoing drought coupled with strict regulations are forcing dairy farmers to continually become more efficient in growing their crops to feed their cows.

“Often times, we find ourselves stressing one crop to water another” he notes. “The state needs to do a better job managing our water better. A big concern of mine isn’t how much water the state already redirects away from the rural areas, but whether they will try and steal even more of it away from us in the future.”

Reviewing their balance sheets and bringing in team members, the conversations are unfolding on dairy farms across the U.S., as producers delve into what technologies can serve as a launchpad to get their dairy to the next level. One thing is for certain: Producers are weighing out the challenges and opportunities each investment offers, focusing on the ROI that will help spell longevity for their dairy.