Focus on the Pen, Not Individual Cows, to Deliver Profits

Monitoring what's happening at the pen level, rather than for individual dairy cows, is proving to be the best approach for producers with more than 1,000 cows. It allows them to prevent and predict health or feeding issues cost effectively, and hence, increase farm profitability. The ‘power of the pen’ philosophy is leading to changes in how farms feed, vaccinate and manage their cows. Technology is enabling and in fact accelerating this trend.

Farmers have spent hundreds of years checking up on each cow, making sure they are fed and that workers are following best practices. While this is effective for herds of 20, 100 or even 200 cows, the approach is very time-consuming, requires a lot of labor and is being replaced by time saving technologies and innovations which eliminate human errors as farms increase in size.

Activity monitors, robots, milk sensors and smart cameras in the barn and parlor are just some of the technologies arriving on U.S. Dairy farms, with the promise of monitoring feed, drinking, milk quality, heat detection and disease. Large U.S. farm owners question the value of tech intended for individual cows on farms when management decisions on large farms address issues at herd level and not for individual cows. “Don’t tell me I have more lame cows or which farms are showing acidosis in a pen. I don’t have the employees to manage on that basis when we milk over 3,000 cows,” one said to me recently. Changes in nutrition, bedding and management are done for all the cows in a pen, not for the individual, if maximising profits is the goal.

Large Dairies Managing by the Pen

As consolidation and expansion continues, driven by the economics of scale, large dairies are managing in terms of pen metrics. The same trends can be seen globally. Today, most U.S. milk cows (55%) are housed on farms with more than 1,000 cows, with nearly 200 farms milking 5,000 cows or more (USDA Census, 2017). Large farms are managed very differently from smaller dairies. Time is even more valuable, unavailable and expensive, so monitoring individual animals and treating them for all issues is simply not an option.

Larger farms require different technology than medium and small ones. This may be seen clearly in the technology being used. Farms with more than 3,000 cows are unlikely to use technology that requires substantial hardware investment and specialized labor to manage devices, especially during a time when finding people to manage cows is already a challenge.

Larger farms equally say they don’t want individual cow alerts. Herd managers complain that alerts lead to ‘fire-fighting’ and quickly pile up, disrupting daily management. Heat detection is one of the rare examples of real value of technology, but even so the penetration in the U.S. is still much lower than in Europe, where the smaller farms predominate.

Conversely, pen level data delivers valuable, real-time insights into performance and allows large dairies to identify the early warnings that problems are developing, rather than fixing them when they already exist. Changes in cow behaviour through methods such as the CowSignals® audits is the most proactive way to solve problems. “Find the signs that indicate the problems that cause cows to get sick instead of finding another sick cow,” founder Dr. Joep Driessen says. Pen metrics are the best early warning system for preventing health problems down the line.

The 24-hour cow time budget is another way to do that. Measuring the time that cows spend lying, standing, out of pen or eating is invaluable to improve farm profits. High yielding cows that lay down longer maximize milk production and their welfare. Experts say farms should target a minimum of 12 hours of rest per day, and the out of pen time (time spent in the milking parlor) should be minimized. Every hour not spent feeding or resting and ruminating directly impacts health and performance. For large dairies, group level information is crucial to keep an eye on production, health and welfare. If the herdsman knows 85% of the pen averages 12 hours lying time or more, there is no need to intervene. When out of pen time is too high, for example more than 4 hours per day, it can lead to increased lameness and certainly lower feed intakes. Producers may address this through changing the milking routine or waiting time before milking.

Always Keep Feed in Front of the Cows

With feed costs rising and now close to 60% of the cost of production, ensuring enough feed is front of the cows is of key importance to optimize intakes and ensure milk production is maximized. Pens with low feed intake for 2 or more hours will compromise milk production, and feed availability is especially crucial post-milking. Identification of pens with low feed intake and specific sections within each pen allows farmers to prioritize where to have feed delivered right away. Targeting this also reduces the time between clean out and feed delivery. Managing feed in the pen ensures feed intake and hence milk production is stimulated, with less feed wasted and cost savings maximized.

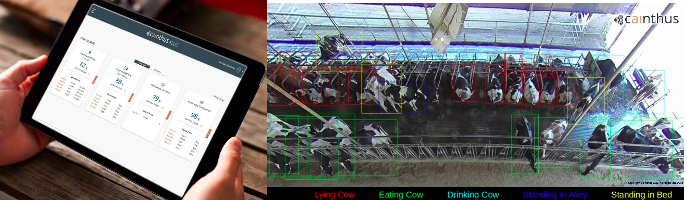

Smart Cameras to Watch Over Pens

The application of cameras in the barn and the parlor continues to grow. Smart cameras are ideal for dairies because they can monitor pens 24 hours per day, 365 days per year, without affecting the cow. In addition, the use of cameras is easily scalable, with low level of maintenance and breakdown required. Cameras detect trends and anomalies at the pen level at an early stage, identifying the warning signs.

Steve Maddox Jr., of Maddox Dairy in Riverdale, California, has embraced smart cameras monitoring groups of cows at the pen level, along with certain areas of the barn. Maddox’s experience is that the most useful camera data has come from the feed bunk. Showing which pen needs attention right away and confirming that specific cows love to eat in one spot of the feed bunk more than others. As a result, their feeders now drop more feed where cows like to eat. “As managers of a large dairy, you have to find ways to see things when you are not there. Now we can see exactly what is being done and when, which is beneficial for us”, Maddox explains.

Modern Management

Working with pen level insights doesn’t mean the individual cow is forgotten. Every individual animal has its own intrinsic value and should be given the care and attention when needed. However, the use of pen level insights fits the modern management style of large farms and can improve feed and health management, detecting changes in behaviour and feed availability earlier. Of the current wave of novel technologies, the use of smart cameras seems to be the most affordable and adapted to precision feed management, increasing feed intakes, maximizing labor efficiencies and reducing feed costs. It also ensures best practices in pen operation management by maximizing a cow’s productive time. The ‘power of the pen’ is truly transforming the profitability of large dairies.