The Nitty Gritty on Hyperkeratosis

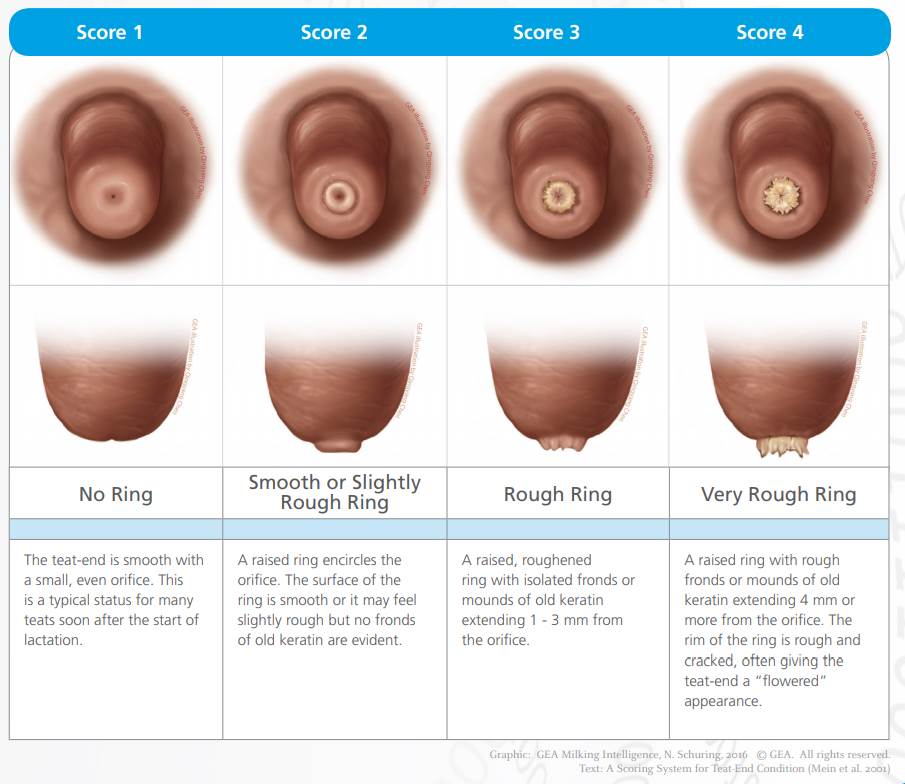

Hyperkeratosis. It’s a word most producers never use, but it’s a common occurrence on most dairies. More frequently referred to as ‘rough teat ends,’ hyperkeratosis is the production of excess keratin at the end of the teat canal which causes a rough, bacteria-harboring, calloused surface. Slightly affected teats will show a raised ring around the teat orifice with highly affected teats showing a raised, rough ring around the teat-end with mounds of old keratin extending 1-4 mm. The rim of the ring is rough and cracked, often giving the teat-end a “flowered” or “blown-open” appearance.

“Keratin isn’t bad. It’s a waxy, sticky substance that helps the teat end close after milking and prevents bacteria from mobilizing into the canal,” says Keith Engel, Business Development Manager in Hygiene at GEA. “Excess keratin, however, can lead to milk quality issues as bacteria builds up.”

Causes

According to Engel, many things can lead to an excess buildup of keratin, with one of the first being the animal’s genetics. “Long, narrow, pointy teats have less surface area than animals with round or flat teat ends,” Engel explains. “The same amount of vacuum pressure is put on all teats, so cows with less surface area compared to cows with a flatter teat are more prone to rough teat ends.”

Another common cause is improper pre-milking procedures. “If you don't prep cows correctly, this affects milk letdown and can cause cows to have low milk flow at the start of milking. Under low milk flow, the level of vacuum on the teat end increases (closer to system vacuum) which causes keratin to start growing in excess,” Engel explains. The same effect happens when cows are overmilked and milk flow is low. Consistency in proper udder prep and taking units off on time is key.

Weather and temperature changes can also lead to rough teat ends, Engel notes. Cold, windy weather can cause dry teat ends. Using the proper teat dip best suited for temperature changes can help ward off this annoying condition. Other common causes of hyperkeratosis include leaving the milking machine on for too long and improper vacuum levels.

Prevention

While you can treat hyperkeratosis with exfoliating and softening teat dips and proper care, the best solution is always prevention.

“Make sure to service your milking equipment regularly and the settings are optimal for your dairy,” Engel recommends. “Another key factor is using the right teat dips for your cows’ environment to ensure teats are conditioned properly – be proactive before the weather gets cold. Look over your pre-milking procedure to ensure proper milk letdown and teat-end cleaning to prevent excess keratin buildup.”

Another key factor to monitor is facility maintenance. “Facility and bedding maintenance is really important. If you have wet bedding and don’t have proper wind blocks, it will adversely affect teat-end health,” Engel warns. “Monitor your environment and keep it dry. Having wind blocks and curtains can help ensure you don't subject teats to a cold windchill factor.”

When a problem occurs, analyze the percent of the herd experiencing the problem. To do so, Engel recommends seasonal teat-end scoring. Scoring will help detect the percent of rough and very rough teat ends on a scale from 1 to 4, with 1 being smooth with no keratin ring and 4 being a very rough keratin ring. Herds should always be less than 20% rough (score 3) and very rough (score 4). The scorer should look for long-term teat changes, such as hyperkeratosis, and look and feel for short-term changes such as hardness, color, swelling and soreness. Knowing your herd’s teat health when you feel things are good will help you know where you are at when they are not.